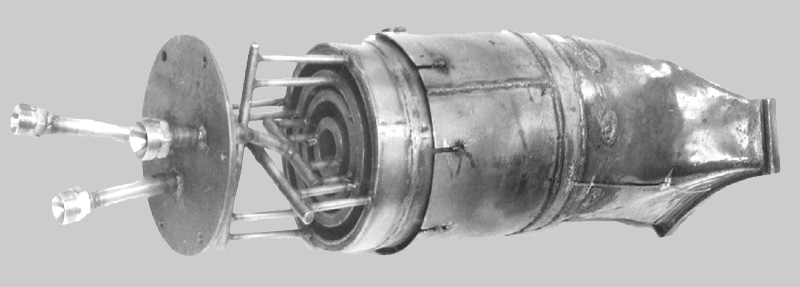

1. Камера сгорания с микродиффузионным фронтовым устройством (КС с МДФУ)

Рис. 1. Зависимость полноты сгорания от коффициента избытка воздуха: топливо – природный газ; Т2 = 35-400С

- 1 – серийная КС ГТ-16

- 2 – опытно-промышленный образец КС с МДФУ

- 3 – область значений для авиационных двигателей (Теория и расчет ВРД. Под ред. С.М. Шляхтенко – М.1987. – 568с.)

Ukraine- 01135, Кiyv-135, Peremoga ave. 16, ap. 34,

phone/fax: (+38 044) 236 82 63, E-mail: mail@ecofakel.com

Our firm has universal technology

We want to represent new universal ecological clean and completely optimized technology of fuel burning.

As a result of purposeful experimental and theoretical investigations of burning processes, aerodynamics and mixing of gaseous and liquid fuels carried out by Dr. Kryzhanovsky during 40 years in the frame-work of his united methodological program, for the first time was developed the general design procedure of combustible gaseous mixtures and liquid fuels characteristics with different compositions and initial parameters.

The following characteristics are being calculated:

— propagation velocity of normal front of flame for mixtures with different compositions;

— width of normal front of flame;

— maximum volume intensity of mixture burning (volume heat-release rate);

— characteristics of combustion stability.

On this base were developed the engineering design procedures of burners and front devices of combustions chambers, including these with extreme characteristics:

— maximum heat-release rate of combustion zone;

— minimum fuel spray length;

— maximum boosting;

— minimum yield of nitric oxides, etc.

Microdiffusion technology of gas burning was realized and investigated for the first time.

It combines in itself the best properties of kinetic and diffusion combustion: the high intensity of the process and wide range of work on the coefficient of air excess.

This technology is unrivalled in the terms of creating combustion chambers of new generations for high-temperature and ecologically clean gas turbine plants (GTP) and also in the case of modernization of existing plants.

It gives the possibility to obtain the most effective solutions concerning the whole range of technico-economic and ecological characteristics alongside with minimum labour input and dimensions of combustion chambers.

On the basis of this technology it is easy to realize cheap and effective combustion chambers modernization of the whole stock of existing GTP-s with substantial increase of economical operation, service life and ecological characteristics.

Designing and engineering procedure of GTP-s combustion chambers characteristics.

“Ecofakel LTD” has design and calculation methods of combustion chambers, operating using gaseous fuel with the temperature on the turbine input up to 1500 °C and giving the possibility to satisfy the customer’s requirement in the best way without subsequent labour-consuming operational development of the tasted.

We have the possibility to provide the best result according to the following requirements:

— Full fuel combustion in a wide range of loads, including idle running ³ 99,9 %;

— Minimum ejections of nitric oxides NOx of 5-25 ppm in the regime of maximum load, depending upon the type of GTR;

— Minimum pressure losses in combustion chambers (³ 1,5 %);

— Provision of necessary temperature pattern uniformity at the combustion chambers exit;

— Minimum combustion chambers walls temperature and service life increase of the most heat-release rate parts of combustion chambers;

— Combustion chambers minimum dimensions (including length);

— Low-temperature starting of GTP.

We can optimize the design according t any total combination of requirements concerning the chambers determined by the customer.

Kinds of work being carrier-out.

1. Development of new combustion chambers for existing GTP-s

2. Designing combustion chambers for perspective GTP-s:

— High-temperature GTP-s;

— GTP-s operating using different gaseous fuels;

— GTP-s operating using hydrogen fuel;

— GTP-s designed according to complex schemes;

— Contact GTP-s;

— Combustion chambers and special purpose reactors.

Different purpose GTP-s combustion chambers modernization.

Present technology is a universal technology and it can be used with any flame-technical device (for driers, furnaces, boilers furnaces, combustion chambers).

As a result of carried out investigations it was determined:

1. The combustion chambers stably operates in the necessary range load change in each of three channels.

2. The start in the 1-st channel is carried out according to the existing requirements.

3. No-load operation regime may be realized both in the 1-st and in the 3-d channel with high degree of burning and ejections of NOx 9,5 – 11,0 ppm.

4. In the regime of maximum load realized in 1 and 3 channels under the heating up to T=760 °C (this temperature is 160°C higher than during the initial engine regime) the output of NOx constituted 8,2 ppm.

5. Aerodynamic drags and temperature field on the exit combust chambers during design were not worse than the inices of the initial prototype.

6. Determined stable, without vibration the operation of the combustion chambers during the operation regime from starting and no-load operation up to maximum load.

7. Obtained result correspond to the technical task of the Contract and confirm the correctness of the results obtained by the Executor previously while designing nozzle unit of combustion chambers for manufactured article GPU-16A.

8. Approximate calculation, carried out for conditions of engineer operation give the possibility to conclude, that on manufactured article GPU-16A maximum output of NOx in all operation regimes will no exceed 40 mg/nm3(02 = 15%).

9. In connection with the fast that in the process of production prototype manufacture were made some deviations from the project it is recommended to carry out finishing of nozzle unit in the following manner.

Literature:

1. Крыжановский В.Н. Феноменологические основы теории горения газов: автореф. дис. … докт. ф.-м. наук, Черноголовка, 1986г.- 34с.

2. Kryzhanovskiy, V.N. Resent Developments in the Theory of Combustion of Gases (A Survey). Prom. teplotekhn., 12, No. 4, pp. 549 – 571, 1992 [Heat Transfer Research, Vol. 24, No. 4, 1992].

3. Kryzhanovskiy, V.N. Improvement of Combustion of Gaseous and Liquid Fuels (A Survey). Prom. teplotekhn., 12, No. 3, pp. 65 – 83, 1990 [Heat Transfer Research, Vol. 24, No. 5, pp. 703 – 723, 1992].

Добавить комментарий